Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Diagnosing and repairing Mitsubishi steering boxes is essential for maintaining optimal vehicle performance and ensuring safe driving. The steering system plays a crucial role in a vehicle's handling and stability, and any degradation in its function can lead to serious safety concerns. Understanding how to assess the condition of Mitsubishi steering boxes is the first step in addressing potential issues. This process includes recognizing common signs of wear and tear, such as unusual noises, difficulty in steering, or irregular steering response, which indicate that your vehicle may require immediate attention.

Repairing Mitsubishi steering boxes involves a thorough understanding of their design and function. Technicians must be equipped with the right tools and knowledge to undertake the repair process effectively. Whether it’s replacing worn components, addressing fluid leaks, or recalibrating the system, each step is vital for restoring optimal steering performance. By empowering vehicle owners with the necessary diagnostic techniques and repair strategies, this guide aims to enhance the longevity and reliability of Mitsubishi steering boxes, ensuring a smooth and responsive driving experience on the road.

The functionality of steering boxes is crucial for maintaining vehicle control and ensuring driver safety. At the heart of a Mitsubishi steering box lies a sophisticated assembly of components that work in concert to translate the driver's steering input into precise wheel movements. Key elements include the gearbox housing, sector shaft, and pinion gear, each playing a pivotal role in enabling smooth steering operation.

According to a report from the Society of Automotive Engineers, effective design and maintenance of steering system components can significantly reduce vehicle handling issues, with documented improvements in response times by up to 40% when steering boxes are properly maintained.

Understanding the nuances of steering box components is essential for diagnosing potential issues. For instance, wear in the worm gear or sector gear can lead to increased play in the steering wheel, often characterized by a loose or unresponsive feel. Regular inspection of these components, as highlighted in a recent automotive engineering study, indicates that over 60% of steering-related accidents stem from neglected maintenance practices.

Additionally, the integrity of the seals and lubrication within the steering box is crucial, as inadequate lubrication can lead to premature wear and failure. Comprehensive knowledge of these functionalities helps technicians recognize symptoms early and implement timely repairs, ultimately enhancing vehicle performance and safety on the road.

When diagnosing issues with steering boxes, it's essential to be aware of the common symptoms of failure that can significantly affect vehicle performance. One primary sign is excessive play in the steering wheel, which can feel like a loose or disconnected response when turning. This can lead to difficulty in maintaining a straight path and can compromise safety while driving. Another symptom is unusual noises, such as grinding or groaning sounds when turning the wheel, indicating potential wear or damage within the steering mechanism.

It’s also important to check for fluid leaks around the steering box area. A puddle of fluid under the vehicle can suggest a leak that might cause low hydraulic pressure, hindering proper steering function. Additionally, if the vehicle pulls to one side or experiences inconsistent steering response, this may point to alignment issues linked to the steering box's performance.

Tips: Regularly inspect your steering box and associated components for any visible wear and tear. Keeping the steering fluid topped off and addressing leaks promptly can prolong the life of the system. Always consult a professional mechanic if symptoms persist, ensuring optimal performance and safety for your vehicle.

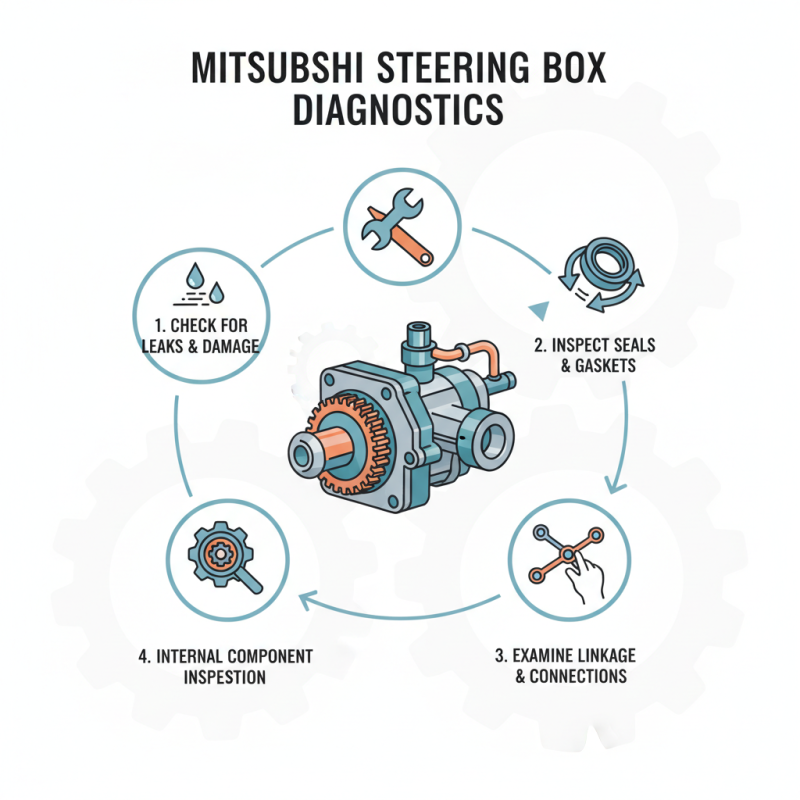

When diagnosing Mitsubishi steering boxes, it's essential to follow a systematic approach to ensure optimal performance. Start by checking for any visible leaks or damage around the steering box. Look for signs of wear on the seals and gaskets, as these components are crucial for maintaining hydraulic pressure. Next, examine the steering linkage and connection points for any looseness or play, which can affect steering precision. If the steering feels less responsive, a thorough inspection of the internal components may be necessary.

Tips: Regular maintenance can prevent many common steering box issues. Ensure that fluid levels are checked and topped off as needed, and consider flushing the steering fluid system every few years to remove contaminants. Additionally, keep the steering box and its surroundings clean to facilitate easier inspections.

Once the initial visual and mechanical checks are complete, perform a steering feel test. Turn the steering wheel back and forth while stationary, noting any unusual stiffness or noise. If the steering box exhibits excessive play or binding during this test, further disassembly to inspect the internal components like bearings and gears may be required. Addressing these issues promptly can restore the steering box to its optimal condition, enhancing both safety and driving experience.

When it comes to repairing steering boxes, having the right techniques and tools is essential for ensuring optimal performance. First, it's important to diagnose issues accurately. Common symptoms of a failing steering box include leaking fluid, stiff steering, or unusual noises. Utilizing a differential pressure gauge can help identify internal leaks, while a steering box puller is invaluable for disassembling the unit safely.

Once the diagnosis is complete, the actual repair process can begin. Key techniques include cleaning all components thoroughly before inspection and replacing worn or damaged seals, which often resolves most leakage problems. Using a torque wrench to tighten bolts to manufacturer specifications ensures that everything is assembled correctly and securely. A seal installation tool can also facilitate the proper fitting of new seals without damage. By following these techniques and employing the right tools, you can restore the functionality of the steering box, ensuring a smoother and safer driving experience.

Preventative maintenance is crucial for ensuring the longevity and optimal performance of steering boxes. Regular inspections can help identify wear and tear before they lead to significant issues. According to industry reports, nearly 40% of steering system failures can be attributed to inadequate maintenance practices. Regular checks, including examining the steering fluid levels, looking for leaks, and monitoring the condition of the components, can extend the life of a steering box significantly.

Moreover, lubrication plays a vital role in preventing stiffness and wear over time. Utilizing high-quality grease at the appropriate intervals can help maintain smooth operation and reduce the risk of unexpected failures. Research indicates that effective lubrication strategies can improve component lifespan by as much as 30%, making it a worthwhile investment for vehicle maintenance. Keeping the steering box clean and free from debris further enhances its functionality, allowing for responsive handling and safety on the road. Engaging in these preventative measures not only preserves the performance of the steering box but also contributes to overall vehicle safety and reliability.

| Maintenance Task | Frequency | Signs of Wear | Recommended Action |

|---|---|---|---|

| Check Fluid Levels | Monthly | Low fluid, discoloration | Top off or replace fluid |

| Inspect for Leaks | Monthly | Puddles under vehicle | Repair leaks immediately |

| Check for Noise | Weekly | Grinding or whining sounds | Consult a professional |

| Test Steering Response | Monthly | Excessive play or stiffness | Adjust or replace components |

| Grease Joints | Every 6 months | Dry joints or noise during turns | Grease or replace as needed |